Smart Mirror Manufacturers

As a smart mirror manufacturer that has been deeply involved in the industry for many years, when communicating with customers, we are often asked about the overall process of manufacturing smart mirrors and whether there are any process difficulties, such as cutting the original glass shape and engraving icons on the finished mirror.

Our usual answer is: Any process difficulty can actually be completed and corrected using corresponding equipment and technology. The most important thing is that customers need to clearly know what kind of products they need, what their application fields are, and what specific needs they need. What are the functions, the certification and packaging regulations of the target market, and the output and input requirements of the appliance.

With these hard targets in mind, we follow these requirements and what we ultimately present is the final perfect mirror that is handed over to our customers. The following is the entire pre- and post-production guide tailored by us as a mirror manufacturer.

How to make a smart mirror?

We can take a look at it one by one:

1. Research and Design:

Market survey:

Conduct market research to understand the actual needs for smart mirrors and identify potential features that customers may want.

Design customization:

Determine whether the customer wants to offer customizable options, such as specific, unconventional sizes, shapes, frame materials, or other add-ons.

2. Select Components (main body + accessories):

Choose a quality mirror:

What we usually recommend to customers is a 4-6mm copper-free silver mirror to ensure the quality of use, whether it is an ordinary two-way mirror or a one-way mirror with a defogging, explosion-proof and other functional film.

Choose accessories:

Choose a suitable and safe power adapter based on customized functions.

3. Develop Production Scheduling Plan:

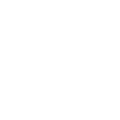

QC:

Quality control measures are implemented to ensure that both mirrors and smart technology meet high standards. Because factories now use automated equipment, accurate machine parameters must be input and verified in each process to debug and complete the final production assembly line.

4. Software Development:

User Interface (UI) Design (Specific)

Some customers require that the mirror be equipped with a touch screen function and realize human-computer interaction. You need to adapt to the mainstream interactive software on the market or create and customize it (generally we recommend the former). Find a professional UI designer to design an intuitive and visually appealing user interface.

5. Mass Production:

Scale production:

Mass production is planned while maintaining quality standards. Consider manufacturing efficiency and cost-effectiveness.

Supply chain management:

Establish a reliable component supply chain, including mirrors, power adapters, explosion-proof films, anti-fog films, hanging films, etc.

6. Testing and Quality Assurance:

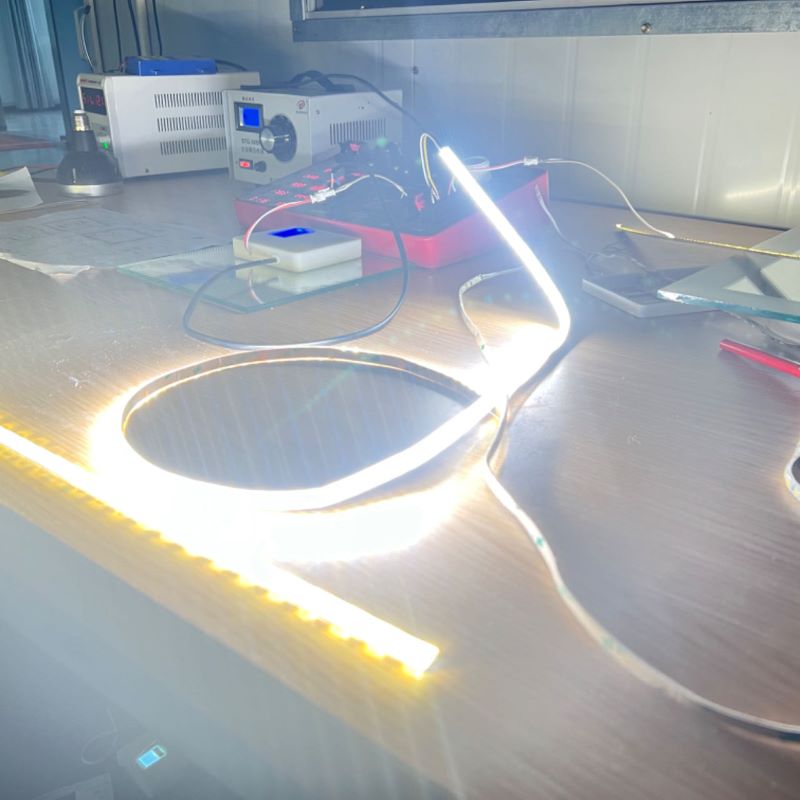

Quality Inspection:

Before each smart mirror unit leaves the manufacturing facility, it undergoes a thorough testing program, including mirror salt spray testing and power aging testing.

7. Logistics

Choose the appropriate shipping method and logistics solution to maximize economy for customers.

8. Customer Support and Warranty:

Provide customer support:

Provide customer support for inquiries, troubleshooting and assistance to build customer trust

9. Compliance and Certification:

Ensure compliance:

First of all, ensure that the packaging is compliant. Before the mirror leaves the factory, we will conduct a box-breaking test with the packaging to review whether the current packaging plan passes the standards. Organize the certification documents of the relevant products as a whole and accessories and provide them to customers.

Therefore, in the process of building smart mirror design and production, it involves communication of early details, determination of hardware and software, and full supervision of the manufacturing process to ensure that the final product meets customer expectations and stands out in the market. This is the greatest sincerity we give to our customers.